Mini Sisyphus Sand Table

Welcome to my Instructable on building your very own Sisyphus table!

What is a Sisyphus table, you ask? It’s a captivating kinetic art piece that uses a steel ball and a layer of sand to create mesmerizing, ever-evolving patterns. I’ve designed and built one from scratch, and now you can too! Imagine creating stunning, one-of-a-kind designs that bring art to life before your eyes.

Hi, I’m Ben, and I’m 15 years old.

My goal with this project was to make the Sisyphus table both affordable and accessible. By using mostly 3D printed parts and inexpensive hobby stepper motors, I was able to keep costs low while still building a high-quality, functional machine. The project also incorporates ball bearings, 3mm metal rods, and some basic electronics. And for an added touch of flair, I’ve included LED lights that can change colors and patterns, making each design even more personal and visually dynamic.

In this guide, I’ll take you through my entire journey of creating a sand table that moves in two axes (X and Y), how I coded it to bring designs to life, and how you can build one too!

I’ll start by explaining the inspiration behind my creation, then walk you through a step-by-step, detailed Instructable so you can make your own. So, without further ado, let’s get started!

Supplies

Materials:

- PLA (Polylactic Acid) Filament – For 3D printing the frame and components (e.g., gantries, motor mounts, and other structural parts).

- Sand – To fill the table for creating patterns. You will need enough sand to cover the surface of the table and allow for smooth movement of the magnet.

- 3mm Metal Rods – Used as the linear rods for the X and Y axes. These rods serve as tracks for the gantries to slide along.

- Timing Belt Kit – For the CoreXY motion system. Includes timing belts and pulleys to drive the motors.

- Magnets (6mm) – To control the ball (marble) and create the sand patterns.

- Fabric (for table surface) – Use fabric to cover the table's surface where the sand will rest. Only glue the corners to prevent the fabric from being too stiff.

- M3 Screws and Nuts – To secure components together, such as mounting the motors and attaching the metal rods and bearings.

- Hot Glue (for some parts) – For attaching components like the fabric and the switch to the frame.

- Ball Bearings – To reduce friction and ensure smooth movement of the gantries along the metal rods.

- Power Supply – To power the ESP32, motors, and other components.

- Heat-set Inserts (optional) – For securing the motors in the 3D-printed parts, making them easier to remove or replace.

Electronics:

- ESP32 Microcontroller – Used to control the system's motors, sensors, and LEDs.

- 28BYJ-48 Stepper Motors and motor driver (x2) – Stepper motors used for the CoreXY movement mechanism. You’ll need two of these for controlling the X and Y axes.

- Limit Switches (x2) – Used for homing the motors and defining the limits of the movement area.

- Potentiometers (x3) – Used to adjust variables like speed or motor torque.

- Buttons (x5) – For user input, such as starting/stopping movement or adjusting settings.

- LED Strip (optional) – For visual effects on the sand table. You can control the LED lighting via the ESP32.

- Switch (x1) – Used for turning the system on or off.

- wire - Used to connect all of the electronics.

Background

I have always loved sand since I was little, whether it was at the beach or in a sandbox. I liked creating intricate designs and shapes that looked cool. When I got my first 3d printer, I printed a zen garden that basically is a mini sand table that you can create patterns in. Ever since then, I always wanted a sisyphus table that could do it automatically. But I never knew how to make it myself and buying one was way too big and expensive. So when I saw this competition I thought it would be a great way to challenge myself by creating a diy sisyphus table. This project ended up challenging me in many ways, including CAD (Fusion 360), coding, and making a core xy system. Now I’m excited to present to you my sisyphus table.

What is a sisyphus table?

A Sisyphus table is like a magical sandbox where a ball dances across the sand, creating beautiful, ever-changing patterns. Imagine a tiny beach where the waves draw pictures for you, only to erase them and start anew. This enchanting table uses a ball that glides smoothly over the sand, crafting intricate designs that seem to come to life.

The secret behind this magic lies in two motors that move the ball using invisible hands—magnets. These motors are guided by a small computer, which acts like a choreographer, directing the ball’s graceful movements. Beneath the sand, a magnet attached to an arm pulls the ball along, drawing patterns without ever touching it directly.

The table uses a clever motion system called CoreXY, which ensures the ball moves with the precision of a skilled artist. As the ball traces its path, it creates mesmerizing designs that are continuously erased and redrawn, much like an endless dance. This perpetual motion is what makes the Sisyphus table so captivating, as it transforms simple sand into a canvas of ever-evolving art.

Planning

Requirements

Before diving into the details of drawing intricate patterns in the sand, I needed to clarify the goals for my Sisyphus table. These essential requirements shape every decision made along the way.

What It Needs to Do

- Create Intricate Patterns

- Purpose: The table’s main job is to create mesmerizing patterns in the sand, like a doodle that flows smoothly across the surface—no jerky lines or missed spots.

- Challenge: To make sure these designs are clear and detailed, the ball’s movement has to be carefully controlled. Think of it like guiding a pen on paper; any slip would leave a messy line, and here, it’s no different.

- CoreXY Solution: To ensure smooth, controlled motion, I chose the CoreXY mechanism. It’s both fast and precise, giving the ball steady movements along any programmed path.

- Affordability

- Objective: This table should be affordable and accessible for DIY enthusiasts. Imagine wanting to build a sandcastle without needing special or expensive materials.

- Solution: Using low-cost components like 3D-printed parts and widely available motors, the table is budget-friendly while still achieving reliable performance. Anyone with a 3D printer can make many of the parts at home, making it an ideal DIY project.

- Ease of Assembly

- Goal: Building this table should be as straightforward as putting together a LEGO set. No one wants to spend hours figuring out where each part goes.

- Solution: Using Design for Assembly principles, the table uses standard, “off-the-shelf” parts and a straightforward design. With clear assembly instructions, anyone—even those new to DIY projects—can put it together with ease.

- Smooth Operation

- Objective: The ball should glide across the sand smoothly, like skating on ice. If it gets stuck, the patterns would look incomplete or bumpy.

- Solution: Using fine sand, strong motors, and the right magnet strength allows the marble to roll effortlessly instead of scraping.

- Aesthetic Appeal

- Goal: This is more than just a sand table; it’s a piece of art. The table should look elegant in any room, adding to the decor rather than standing out awkwardly.

- Solution: The design is sleek and modern, fitting in well in both homes and offices. LED lights around the table enhance the effect, adding depth and making the sand designs more eye-catching and soothing to watch.

- User-Friendly Controls

- Need: Operating the table should be simple, like flipping a light switch. Users should be able to start, stop, or adjust patterns without fuss.

- Solution: Intuitive buttons and clear lights signal the table’s status, making it easy to choose or change patterns.

- Quiet Operation

- Importance: Imagine a peaceful space where a sand art table quietly creates patterns; noisy motors would ruin the ambiance.

- Solution: By choosing low-noise motors and designing to reduce vibration, the table operates quietly, perfect for quiet rooms or workspaces.

- Compact Size

- Objective: The table should fit comfortably in various spaces, from a small desk to a coffee table.

- Solution: Designed to be compact yet functional, it balances size with features, fitting into almost any room without taking up much space.

By meeting these requirements, the Sisyphus table will be beautiful, fun to build, and easy to use. With a clear design in mind, the next step is figuring out how to make it all work.

Questions and Challenges

With a roadmap in place, it was time to tackle some key questions.

What Motors Should I Use?

Stepper motors are ideal for this table because they can move in precise steps, allowing control over the ball’s position and speed. Think of each step as a tiny tick on a clock, making it easy to guide the ball in small, precise movements.

- Initial Option: NEMA 17 Motors

- Benefits: NEMA 17 motors are popular in DIY projects, meaning they have lots of resources and community support.

- Drawbacks: These motors require 12-24 volts, adding the need for a voltage regulator. They’re also larger, which doesn’t fit well with the compact design I envisioned.

- Final Choice: 28BYJ-48 Motors

- Advantages: These motors run on 5 volts, which is compatible with other components and simplifies the setup. They’re small, budget-friendly, and their precision and community support make them the perfect choice.

How Do I Control the Motors?

I initially looked at using an Arduino Nano but found it limited in memory and multitasking ability.

- Challenges with Nano:

- Limited Memory: The Nano can only store about 300 lines of G-code, which would restrict the number of patterns.

- Low Processing Power: It struggles with multitasking, making it hard to manage motor movements, button inputs, and LED control at the same time.

- Solution: ESP32 Microcontroller:

- The ESP32 has much more memory and dual-core processing, making it ideal for multitasking. One core can control the motor while the other handles inputs and LEDs. Plus, it has WiFi and Bluetooth, opening doors for future upgrades.

What Type of Sand Should I Use?

Choosing the right sand is essential. Think of fine sand like smooth paper for a pencil—it lets the ball glide without resistance.

- Fine Sand: Fine grains create smoother patterns and reduce noise, giving a polished look to the designs. I chose fine white sand, as its light color highlights the shadows in the patterns.

- Coarse Sand: Larger grains are rougher and can make the ball’s movement choppy, similar to drawing on rough paper.

What Materials Should I Use for the Frame?

The frame has to be both strong and lightweight. I used a mix of 3D-printed parts and metal rods to balance cost, durability, and stability.

- 3D-Printed Parts: These allow for easy customization and keep the overall weight low, reducing strain on the motors.

- Metal Rods: These add extra strength to the linear rails guiding the ball. Metal rods don’t bend or wear down easily, ensuring long-term stability.

How Do I Keep the Table Compact and Portable?

To make the table approachable for DIY enthusiasts, I designed it to fit within a 215mm x 215mm footprint—the size of most standard 3D printer beds. This compact design makes it a desk-friendly decoration without taking up too much space.

How Do I Ensure the Table is Aesthetically Pleasing?

This table isn’t just functional; it’s meant to captivate. To enhance its visual appeal, I included LED lighting around the edges.

- LEDs: These LEDs add ambient light, creating a relaxing effect as the patterns shift. Users can adjust the color to match the room, making the table both decorative and functional.

These considerations helped shape the Sisyphus table into a beautiful, functional, and accessible project that’s enjoyable to build, use, and admire.

Movement/CoreXY

My sand table’s movement system, similar to an Etch-A-Sketch, uses a magnet to move a marble across sand to create intricate designs. Unlike an Etch-A-Sketch with knobs, my CoreXY system employs two motors to control the marble’s movement in two directions. While an Etch-A-Sketch provides manual control, the CoreXY system offers precise, automated control, creating beautiful and dynamic sand patterns. However, achieving precision is key, and the CoreXY design excels with high-speed and accurate motion for crafting detailed patterns.

My main challenge was deciding how to move the marble with a magnet to create sand patterns, which would require a movement system that’s fast, precise, and capable of smooth transitions across the table’s surface. After exploring several options, each with its strengths and weaknesses, I ultimately chose the CoreXY system after a lot of research, testing, and hands-on exploration. Here’s an overview of the movement systems I considered and why CoreXY emerged as the best choice.

Evaluating Different Movement Mechanisms

- Threaded Rods and Stepper Motors

- How It Works: This setup uses stepper motors with threaded rods, converting rotational motion into precise, linear movement.

- Pros: Threaded rods offer high accuracy, especially over short distances, and are simple to set up with affordable parts.

- Cons: Threaded rods are very slow, moving only about 7mm per minute in my tests. This speed isn’t sufficient for the fluid, dynamic patterns needed for a sand table.

- H-Bot Mechanism

- How It Works: H-Bot is a belt-driven system with an “H”-shaped layout that uses two motors to control motion.

- Pros: It has fewer moving parts and a straightforward belt arrangement, making it relatively simple to build.

- Cons: H-Bot can experience twisting forces that distort movement, affecting pattern accuracy, especially with larger, heavier parts. It also has less stability under load, which would become an issue if I scaled up the design.

- Polar Coordinate System

- How It Works: This system uses a rotating arm that moves radially, allowing for unique circular patterns.

- Pros: Excellent for creating intricate, circular designs and visually captivating radial motion.

- Cons: Polar mechanics are complex and require precise programming, which can be challenging. It’s also less efficient on a rectangular sand table, where linear movement systems are more practical.

Settling on CoreXY

After evaluating my options, CoreXY stood out as one of the most promising movement systems for this project. CoreXY operates with two stepper motors and a crossed-belt setup, providing high-speed and precise movement along two axes. Its unique design means that moving one motor alone produces a diagonal movement, while moving both motors together creates horizontal or vertical motion. This system has several key advantages for a sand table:

- Precision and Efficiency: CoreXY is extremely accurate and handles movement smoothly, making it ideal for the repetitive, delicate paths needed for sand table patterns.

- High Speed: Unlike threaded rods, CoreXY allows for significantly faster movement, enabling more intricate designs without the speed limitations of other mechanisms.

- Compact and Lightweight: The CoreXY layout fits into a compact form factor, perfect for a DIY table that doesn’t occupy too much space.

My Journey with CoreXY

From the start, I was excited to explore CoreXY, but its mechanics were hard to grasp from tutorials alone. It wasn’t immediately clear how moving one motor could cause diagonal movement while both motors together produced straight lines. To bridge this gap, I printed a small CoreXY model from Thingiverse to study its workings up close. Using a 3D-printed TPU belt, I tested both CoreXY mechanics and a DIY belt option simultaneously.

This prototype taught me two important lessons:

- TPU Belt Limitations: TPU wasn’t stable enough for the precision required; it stretched and slipped too much, affecting accuracy.

- Hands-On Understanding: Observing the CoreXY system in real life helped me understand its mechanics much better than any video could.

For anyone planning their own CoreXY build, I highly recommend 3D printing a CoreXY mechanism first. This hands-on study of CoreXY mechanics was invaluable for designing my own setup for the final table.

3d Model/code

1. Linear Rods as Train Tracks

To guide the gantries, I designed two "train tracks" (linear rods) that would keep them moving in a straight line. These rods provide the foundation for movement in two directions: horizontal (X-gantry) and vertical (Y-gantry).

- X-Gantry: Think of this as a toy train that only moves left and right along the horizontal rod.

- Y-Gantry: This acts like a train moving forward and backward along the vertical rod.

By combining these two movements, the gantries can cover the entire surface of the mat, just like the toy trains can cover the play area by moving in both directions.

2. Setting Up the "Slider Joints" (to keep the parts on track)

In Fusion 360, I needed a way to ensure that the gantries stay on track and don’t wobble. To do this, I used "slider joints."

- These slider joints are like rails guiding the toy trains. They ensure the gantries only move in their designated directions — horizontally for the X-gantry and vertically for the Y-gantry.

- These joints are like invisible hands that keep the gantries aligned and on their tracks, ensuring smooth and stable movement without falling off course.

3. Applying Slider Joints to Each Gantry

- For the X-gantry (left-right movement), I attached a slider joint that only allows horizontal motion.

- For the Y-gantry (front-back movement), I applied a similar slider joint, but for vertical motion.

This ensures that each gantry stays firmly on its track and can only move in the intended direction, much like toy trains that follow their designated tracks.

4. Testing Their Movement

Once the slider joints were set up, I tested the gantries in Fusion 360 by moving them along their tracks. This allowed me to verify that they stayed aligned and moved smoothly without wobbling or twisting.

Just like pushing toy trains back and forth to ensure they stay on track, I tested the virtual gantries to confirm their movement was stable and precise.

5. Combining Their Moves

Once both gantries were in place, I could now move them across the play mat, covering every area.

By combining horizontal and vertical moves, the gantries could cover the entire surface. It's just like how you can use the two toy trains to cover a whole play mat by moving them in different directions, ensuring all spots are reached.

Coding the CoreXY Setup for Sand Patterns

1. Hardware Setup

In the CoreXY system, I use two stepper motors (like magic hands) to control the movement of the marker (which draws the sand patterns). There are also limit switches that act like invisible walls, helping the system know where the starting point is. This process is called homing.

- The limit switches act as bumpers to ensure the marker starts at the correct position every time, just like knowing where your starting point is in a game.

2. Configuring the Table's Movement

To ensure smooth movement, we need to configure how far, how fast, and how smoothly the marker moves. It’s like setting up a race track where you control the speed and the way the car takes turns.

By determining these movement parameters, we can make sure the marker draws consistently, accurately, and quickly to create beautiful sand patterns.

3. Understanding the G-code Instructions

Each G-code command is like a little treasure map, providing instructions for the marker on where to move. For instance, a command like G1 X115 Y122 tells the marker to move to the point (115, 122) on the surface.

- G1 is the command for movement.

- X and Y indicate the coordinates where the marker should go.

Think of each G-code command as a specific set of directions, telling the marker exactly where to move next.

4. Moving the Marker with CoreXY Magic

The CoreXY movement system works by using two motors, which can move the marker diagonally or along straight lines, depending on how the motors are controlled.

- If both motors are moved evenly, the marker goes straight in either the X or Y direction.

- If one motor is moved more than the other, the marker moves diagonally.

This coordination of the motors ensures that the marker moves smoothly along the correct path without jerking or veering off course.

5. Absolute vs. Relative Positioning (G90 vs. G91)

- G90 (Absolute Positioning): Every command gives an exact position for the marker to move to, like a specific point on a map. Each instruction tells the marker to go to a particular destination.

- G91 (Relative Positioning): This command tells the marker to move a certain distance from its current position. This is like taking steps without a fixed destination, which could lead to a wandering movement.

For sand pattern creation, absolute positioning (G90) is preferred, as it ensures the marker always reaches the exact position without error, like following a precise set of instructions on a treasure map.

By coding the movement using G-code and configuring the system accordingly, the CoreXY setup can smoothly and accurately draw beautiful, intricate sand patterns. The combination of precise hardware and well-defined instructions in G-code makes it possible to create consistent and captivating designs every time.

You can download the 3D model files and G-code at the bottom for further.

Assembly

To begin the assembly, we’ll start with soldering and some pre-assembly steps.

Soldering the Limit Switches:

First, solder two limit switches. Each switch has three pins labeled C (Common), NC (Normally Closed), and NO (Normally Open). You need to wire the C pin for common and the NC pin for normally closed.

Soldering the Buttons:

Next, solder the five buttons. Each button needs two wires: one for ground and one for the signal.

Preparing the Potentiometers:

To save space, use wire cutters to trim the potentiometers. Fix them in place using glue if needed, but they will be secured with screws later.

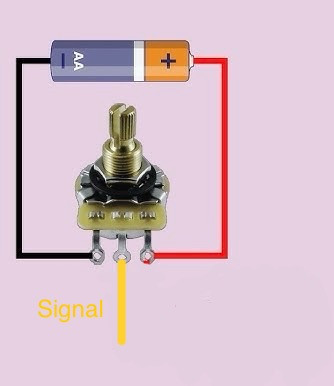

Soldering the Potentiometers:

Solder the potentiometers, connecting the three pins as follows: positive, signal, and ground. The wiring might look confusing, so refer to the next picture for clarity.

Managing the Wires:

You should end up with ten wires: three signal wires from the potentiometers, five signal wires from the buttons, and positive and negative wires. Verify the total number of wires is ten.

Wiring the Switch:

The switch works by opening or closing the circuit. Solder two black wires to the switch, which will open or close the ground connection.

Inserting the Switch:

Insert the switch into its slot. It should press in and fit snugly. You can secure it with glue on the other side.

Adding LEDs:

If you choose to add LEDs, first measure the correct length by wrapping the strip around the top. Wire the LEDs twice due to their low voltage. (Voltage drop occurs when the electrical current travels through the wire, causing a decrease in voltage. Wiring power to the LEDs twice helps maintain consistent brightness.) Reveal the copper contacts and solder the connections.

Assembling the Main Frame:

Now, let’s work on the main frame that holds the motors. First, heat-set the screws into the frame. If you don’t plan to reuse the motors, you can glue them instead.

Mounting the Motors:

Secure the motors in place by screwing them into the frame.

Installing the X-Axis:

Add the metal linear rods for the X-axis and attach the X-axis gantry.

Installing the Y-Axis:

Insert the Y-axis linear rods and the gantry system.

Inserting the Bearings:

Insert the metal rod and then the ball bearings. This is part of the pulley mechanism in the CoreXY system. The ball bearings help reduce friction and ensure smooth movement.

Attaching the Pulley Gears:

Attach the pulley gears to the motors. Each pulley gear has two screws. Align one of the screws with the flat side of the motor shaft for a secure fit.

Adding the Belts:

First, add the belt for motor A. It might be hard to see, so look at the image carefully. Temporarily glue the belt to part 1 of the carriage.

Next, add the belt for motor B. Align it, cut it to size, and temporarily glue it to part 2 of the carriage.

Securing the Belts:

Insert a nut into part 3 and then insert the screw into part 2.

Screw it in to make the connection permanent but still adjustable if needed.

Gluing the Limit Switches:

Glue the limit switches in place. They should align perfectly with both axes.

Lubricating the Rods (optional):

Lubricate the rods to ensure smooth movement. This isn't required, but I HIGHLY recommend doing it for better long term operation and more pleasing creations.

Adding the Magnets:

Add a few 6mm magnets. These will control the ball, so make sure they are strong enough.

Attaching the Fabric(optional):

Glue the fabric to the table. Use hot glue and only glue the corners to avoid making the fabric too stiff. This is optional but I recommend doing it to reduce friction on the ball and make it quieter.

Assembling the Top and Base:

Glue the main top (brown) to the base cover (white).

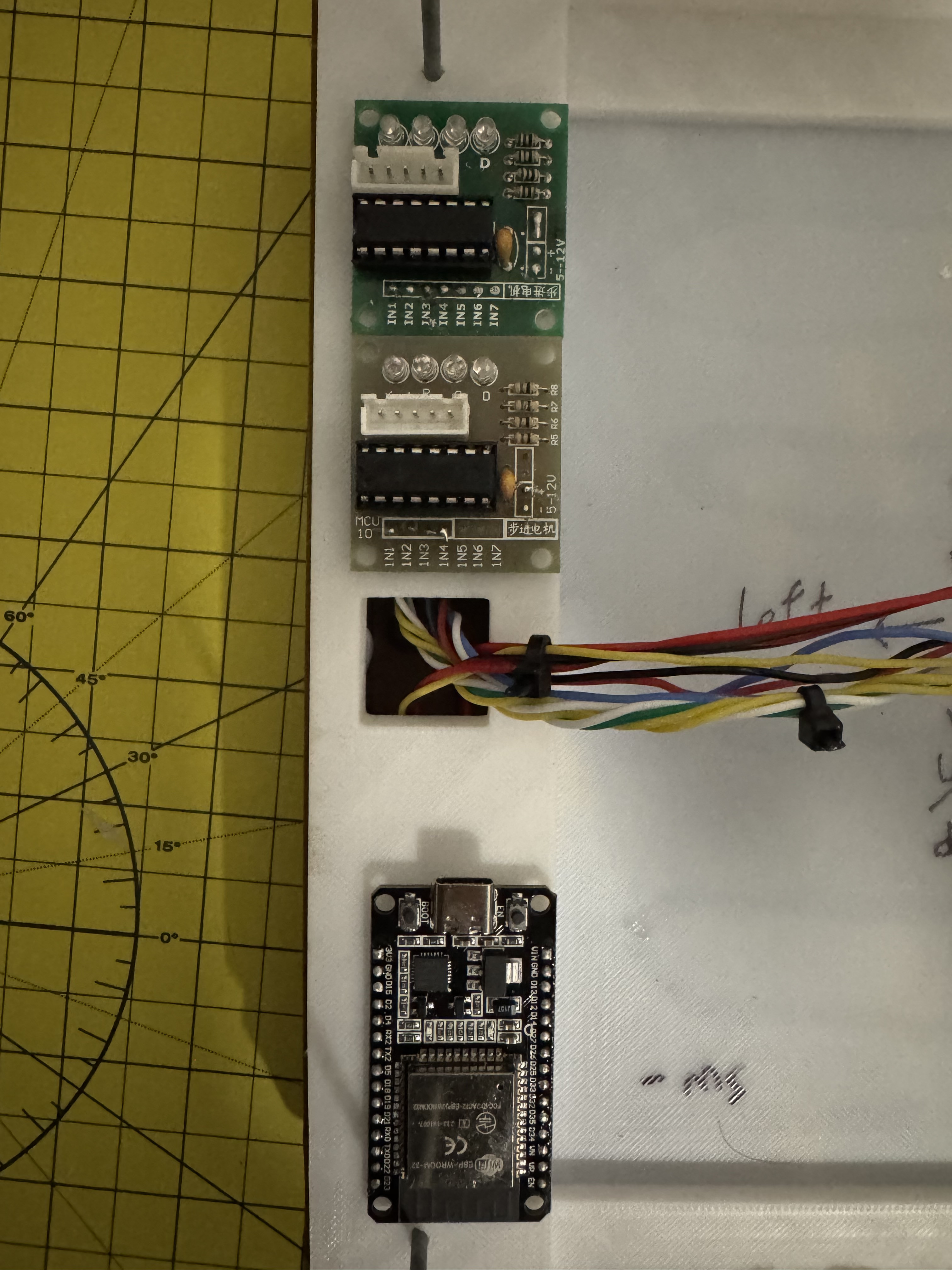

*Make sure you uploaded the code to the ESP32*

Then, glue the three boards: ESP32, motor driver A, and motor driver B.

Soldering the Wires:

Solder all the wires, connecting the motor drivers and inputs to the ESP32.

Final Assembly:

Glue the base cover (white) to the main frame (black). Finish the wiring.

3D print the large base cover.

Attach the large base to the main frame with three screws.

Lastly you just need to fill it up with sand and power it on! You'll have to play

Congratulations! You’ve successfully built your own DIY sand table. Enjoy watching the mesmerizing patterns it creates!

If you have any more questions or need further assistance, feel free to ask!

Diy Patterns/Time-lapses

Now that you’ve successfully built your sand table, you can either use the premade patterns from my code or create your own unique sand patterns. To make your own, you’ll need to convert shapes into G-code. While there are several apps available for this, my personal favorite is Sandify. It's easy to use and comes with clear instructions, along with helpful YouTube videos that walk you through the process step by step.

Once you open Sandify, the first thing you'll need to do is configure the machine settings to match those of your sand table. After that, you can have fun creating your own custom patterns. No two designs will ever be the same, and you can experiment with different shapes, sizes, and patterns to make your sand table truly unique.

Here's a simple guide for creating DIY patterns:

- Open Sandify: Launch the app, and configure the machine settings for your sand table (you can insert the machine settings photo here to give a visual reference).

- Create Your Design: Experiment with the pattern creation tools in Sandify. It’s a user-friendly interface that allows you to easily draw, tweak, and modify designs.

- Generate the G-code: Once you're happy with your design, export the G-code. This code will tell your table's motors how to move the marker to create the pattern in the sand.

- Test the Design: Run the pattern on your sand table and tweak it if necessary. Some trial and error may be required to get it just right.

Pros and Cons of a Small Sand Table

Most sand tables are quite large, typically coffee table-sized or even bigger. While these larger tables can create stunning designs, they also come with a hefty price tag. With a smaller sand table, you get a more compact, affordable option. Here are the pros and cons of working with a small sand table:

Pros

- Quick Pattern Creation: The smaller table allows for quicker patterns, meaning you can watch the entire design be created and completed within 15-30 minutes. This can be very satisfying if you're interested in seeing your designs come to life.

real life speed

- Compact Size: The smaller table can be placed in any room or location, making it very versatile. You don’t need a large space to enjoy it.

- Affordability: Small sand tables are much more affordable compared to their larger counterparts, making them accessible to more people.

- Customizable Designs: You have the flexibility to create any design you can imagine, adjusting parameters in Sandify or your code to suit your preferences.

- LED Customization: You can modify the LED coloring at any time, adding another level of customization to your table’s appearance.

Cons

- Limited Sand Capacity: Due to the smaller size, you have less sand to work with, meaning larger designs or intricate wordings might be harder to achieve effectively. The available sand area may not be enough to create larger or more detailed patterns.

- Potential for Tipping: Since the sand table is small and placed on top of another piece of furniture, there’s a risk that it could tip over if not carefully secured. This may be something to consider when choosing where to place your table.

- Reduced Detail in Designs: Because the table is small, you may not be able to capture as much detail as you could on a larger table. For example, I attempted to create the Instructable logo but couldn’t achieve the level of detail I hoped for despite trying smaller marbles to improve precision. The results didn’t match the expectations from the G-code preview.

- In summary, while a smaller sand table might not be able to show large, intricate designs or precise text, it offers a compact, affordable solution that’s customizable and easy to use. The ability to modify LED colors and design your own patterns makes it a fun and engaging project, perfect for quick experimentation and watching satisfying, fluid patterns unfold in real-time.

Next Step Forward / Conclusion

Next Step Forward

As I look towards improving my sand table, I’ve identified a few key upgrades that will enhance its performance, expand its potential, and refine its overall functionality. Here are the steps I plan to take moving forward:

1. Upgrading the CoreXY Mechanism

One of the main issues I’ve encountered with my current CoreXY setup is the way the belts are arranged. The belts are crossed, which reduces space when moving to far in that direction, negatively impacting performance. To eliminate this, I plan to remake the design with a better belt layout. This will prevent the interference that affects the size of the patterns the table can draw

Additionally, while my design was initially rectangular, I have a lot of wasted pattern area due to the design. I would plan on making a square layout which would use up every inch that the motors could move. The square will also make the overall design and patterns look better as it will be symmetrical.

2. Improving the microcontroller Performance

Another issue I’ve faced is the flickering of the LEDs sometimes during operation if there are too many things happening at once. This is a result of the ESP32 microcontroller not having enough available RAM to simultaneously run the LEDs, process G-code commands, and control the motors. This overloading leads to interruptions in the smooth flow of the system.

To solve this, I plan to upgrade to a Raspberry Pi like the Raspberry Pi Zero 2 W. The Raspberry Pi microcontroller offers significantly more processing power and RAM compared to the ESP32, allowing for smoother integration of the LED system, motor control, and G-code processing. This upgrade will not only eliminate the flickering but will also allow me to expand my project with a much larger codebase. With this enhanced processing capability, I could create and store hundreds of patterns, each with thousands of lines of G-code, and seamlessly run them without any performance degradation.

3. Expanding the Table Size

As 3D printing technology continues to evolve, with machines like the Bambu Lab P1 and A1 series offering larger printing sizes, I’ve considered the possibility of increasing the size of my sand table. Currently, the table is limited in terms of sand capacity and the complexity of patterns it can display due to its size. By upgrading to a 250mm table size, I would significantly increase the sand capacity, providing more room for intricate and large-scale designs.

This larger surface area would allow for more detailed and complex patterns to be created, expanding the possibilities for what I can achieve with the sand table. I envision being able to experiment with more dynamic, sweeping designs that require a larger workspace, while still maintaining the precision and elegance that the CoreXY system offers.

Conclusion

After years of dreaming about creating my own Sisyphus table, I’ve finally brought the idea to life! While my sand table may not match the size or level of detail seen in the commercial versions that can cost thousands of dollars, the satisfaction of building it myself and placing it in my workshop has been incredibly rewarding. The smaller size allows me to watch patterns emerge in real-time, creating a quick and satisfying experience.

The quiet operation of the motors, combined with the vibrant LED lighting, creates a mesmerizing effect that is both calming and Zen-like. Watching the marble move across the table and trace intricate designs in the sand is an experience that’s both peaceful and engaging.

Looking ahead, I’m excited to continue improving and expanding the sand table, implementing the upgrades mentioned above to make it more efficient and capable of running larger, more complex designs. The future holds endless possibilities for this project, and I’m eager to push the limits of what it can do.

Thank you for following along with my journey in this Instructable! I hope you found it both helpful and inspiring. If you have any questions, comments, or suggestions for improvements, please feel free to share them. I’m always open to feedback and love hearing about others’ experiences with similar projects!