School Rubber Band Helicopter

Final Product: After all edits, tweeks, and rearrangements, our final helicopter came out like this.

Supplies

Material List: Two prebuilt plastic blades, two beads, one rubber band, four paper clips, one Stir Stick.

Researcing the Problem

We identified our problem for this project as getting the helicopter to fly using only rubber bands as power. We started researching by finding ways to use elastic energy to propel a blade. Then we looked at materials that were light and strong enough to construct our helicopter. Finally we had to design the helicopter blades to make the helicopter actually fly.

Sources

The information that we used was obtained from both our combined brainstorming and internet research. We all thought of the idea to wrap the blades in rubber bands, and Mr. Stark gave us the idea to have dual wings, one on the top and one on the bottom. We got the idea of twisting the rubber band by watching videos of people creating similar helicopters on YouTube, and then applying that to our own project.

Formulating a Solution

Once receiving this task, we devised a plan on how to make the wings spin, and decided on a hinge-less helicopter concept. Wrap the rubber band around both the blades and the body of the plane, and twist up both and wind them up to build up potential energy and then let it go to turn it into kinetic energy and get the blades to spin.

Materials and Skills

For the body an unbent paperclip was used as an axle. Balsa wood was wet, and curved by being wedged into perpendicular slots. Breads were then super glued in the center of the blade afterward because it has very little friction spinning on the paperclip. There is also a bead above and below the blade's bead for even more reduced friction.

Materials/tools

Balsa wood for the first wings

Rubber Bands for spinning the wings

Paperclip for the base

Premade helicopter blades

Pliers to straighten the paperclips

Wire cutters to trim the paperclips

Super glue for the beads in the original design

Beads in the early stages, were used as a ball bearing

Plastic tubing to cover the paperclip

Testing

Upon testing our helicopter would not lift up at all. We figured it may have to do with the blades we made not being constructed well, so we began to brainstorm ideas for new blades.

Improvements

Looking at other great helicopters we realized that we needed to decrease as much resistance as possible. We tied the band in the middle so it would twist separately, we super glued beads to the propeller to allow the blades to spin smoother on the paper clip base.

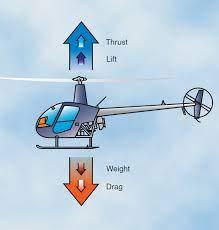

Forces on the Helicopter

The main forces to think about when you are making something that flys is the lift from the blades and gravity pulling everything down. We made propellers that pushed a lot of air down which creates more uplift. The force that we did not get down was the entire body spinning rather than the wings because it is skinny. In order to overcome that obstacle we needed to use a counter rotational force equal to it to het the body steady and the propeller spinning. This was the downfall of our helicopter as we never were able to balance these rotational forces.

Final Touches

After testing the new improvements made to our helicopter, it still seemed to not lift off. For our final improvement, we decided to replace our wooden blades with premade plastic ones. This last change only slightly improved the flight of our helicopter, but nonetheless, an improvement is an improvement.