TUBE BENDER (with Hidraulic Jack)

by igggv in Workshop > Metalworking

3310 Views, 54 Favorites, 0 Comments

TUBE BENDER (with Hidraulic Jack)

I have a project for which I need to bend tubes, to make a structure. And for this need I made this tool. In this

video you can see how it works.

It is not necessary to make the entire structure, if you have a hydraulic press. In this video you can see how:

However, it is better to make the structure with a hydraulic jack, because in this way the tube bends upwards and there is nothing to hinder or disturb, as if it happens when bending the tube in a hydraulic press.

Supplies

I understand that you need very specialized tools and that not everyone has, such as a lathe and milling machine.

Materials

1 hydraulic jack

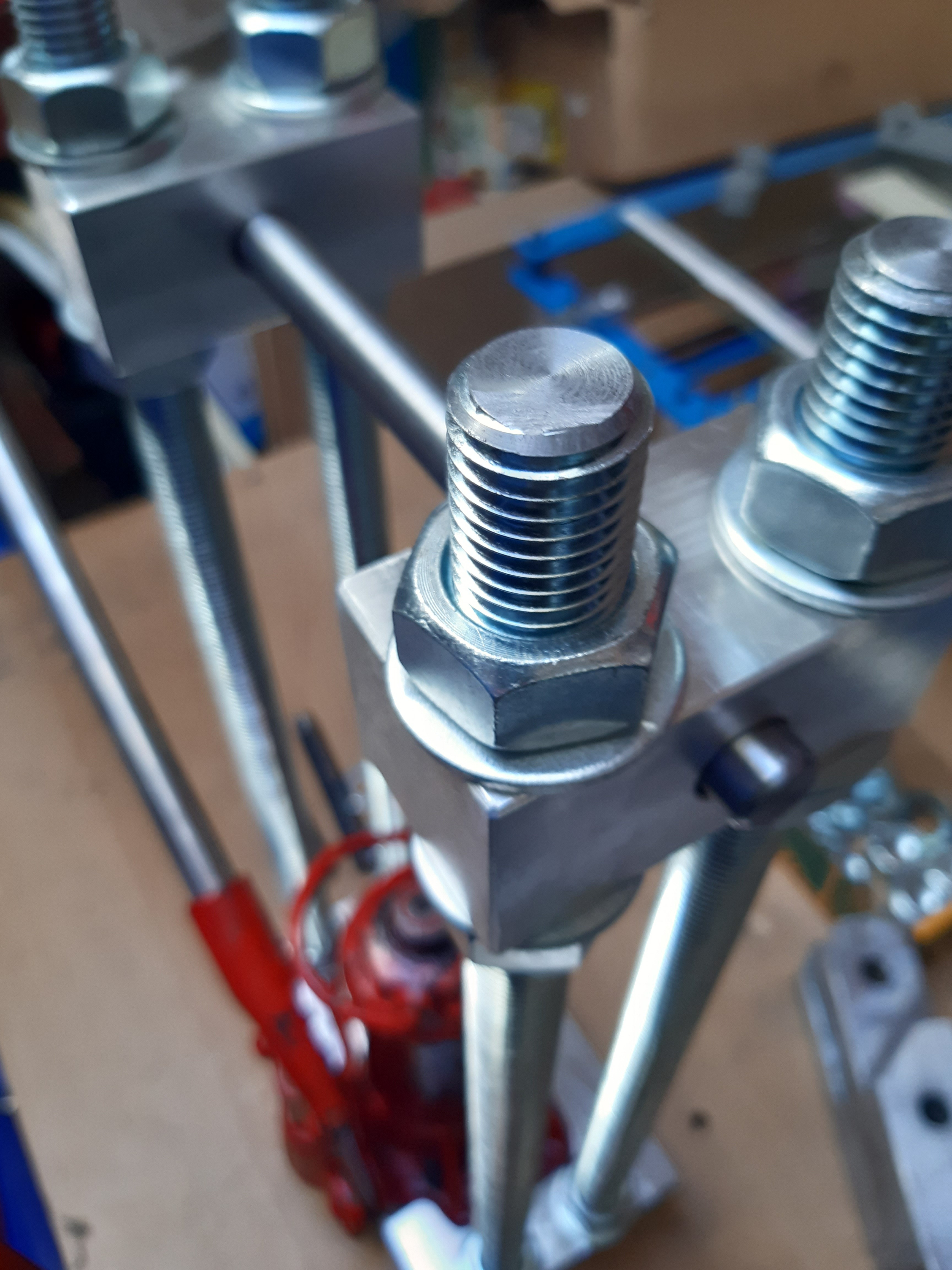

4 threaded rod M20 500mm long

12 nuts M20

12 washers M20

2 axes diameter 15mm and 115mm long

1 axis diameter 15mm and 240mm long

4 washers M14

1 piece like the one in photo 2. 300x100x15

I have welded a piece to fit the hydraulic jack spindle and it can be held in place without it falling off.

3 wheels as in photo 3, one large and two small.

4 pieces like the one in the photo 4

1 piece like the one in photo 5

2 pieces like the one in photo 6

ASSEMBLY

ASSEMBLY

ASSEMBLY

ASSEMBLY

ASSEMBLY

Sometimes, after bending a tube, it is necessary to remove the larger wheel in order to remove the tube.

ASSEMBLY

READY TO USE

Greetings and have fun.

MEASURE

To know how much to bend, it is best to measure the distance between the base and the part that is placed on the spindle of the hydraulic jack. For example, the first time you bend at 90 degrees you write down that measurement, and the following times it will be easier and faster.

IN HYDRAULIC PRESS

To use the tube bender on a hydraulic press I have made a part with a recess that has the outside diameter of the large wheel so as not to push directly on this wheel.