Using Tinkercad to Create a Strip Cutting Tool

1013 Views, 14 Favorites, 0 Comments

Using Tinkercad to Create a Strip Cutting Tool

Every table top wargamer needs scenery and half the fun is building it yourself. To make things like this modular wall (from a Black Magic Craft tutorial here), you need to be able to accurately cut strips. Many of us don't have hot wire cutters and even if we do, it's nice to have a quick and easy tool that cuts cleanly with no melting and without casting 'Stinking Cloud' level 2 in our crafting rooms.

When I bought my house, I found a few tools in the corner of an old shed, including a leather cutting tool for making laces. I found the tool perfect for cutting styrofoam strips (see pictures), so useful that I wanted another one for my son to use when we craft together.

I decided to use Tinkercad to draft up a version without the handle (which I find gets in the way) to 3D print so I could make as many copies as I wanted.

If you want to follow the drafting process, it's a great learning experience. If you just need the tool, skip ahead to the printing step, the files are attached there.

Supplies

Tinkercad (sign up for free at tinkercad.com)

A 3D printer or an online 3D printing service

A few bits of hardware. I used two M3x25 screws to hold the blade on and a 10-24 x 1 1/2" machine screw with a nut for the adjusting thumbscrew knob (or try an M4x35 or M5x35 screw)

A blade - either a scalpel blade (X-acto blade) or a piece of 9mm break-away blade from small craft knife works well.

Drafting the Fence

To draft the fence, I created a 25mm high x 25mm wide x 110mm long box in Tinkercad. Click the ruler button and drag a ruler to the front bottom left corner of the piece. It makes the next steps much easier.

Now, create a box 'hole' that is 13.5mm high x 27mm wide x 25mm long. Position it by typing in the values (-1, 12.5, 15) as shown in the image.

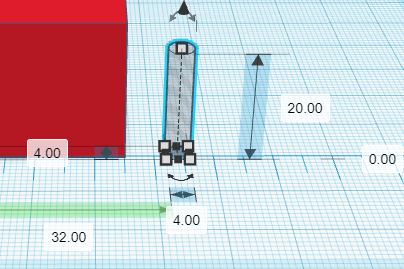

Group the two boxes. Now draft a cylinder 'hole' that is 4mm x 4mm x 20mm high. Position it by typing the values (10.5, 23.5) as shown in the image. This is the hole for the adjustment screw to tighten into. We've made it a bit undersized so that it can be drilled to fit whatever hardware you're using.

Group the cylinder with the fence to finish this part.

Drafting the Adjustment Bar

Create a box 25x25x110mm to be the adjustment bar. Move the ruler to the bottom left corner of the box.

We need a slot cut through the bar to allow adjustment. Create a box 'hole' that is 5mm wide, 27mm high and 85mm long. To tidy the ends up, create two cylinder 'holes' that are 5mm x 5mm x 27 mm high. Drag them onto the ends of the box 'hole'. I needed to type in half millimetre values to get things lined up perfectly. Group the two cylinders with the box hole.

Drag the hole so that it is centred horizontally on the adjustment bar block, 15mm back from the front edge. Group it with the bar.

Now, create a cylinder 'hole' for the blade mounting screws, 3mm x 3mm x 20mm long. Rotate it 90 degrees as shown, then position it 11mm up and 4mm from the left edge of the shape. Copy it (ctrl-c) and paste it (ctrl-v), then position the copy 11mm up and 18mm from the left edge of the shape. Group both holes with the adjustment bar, which is now complete.

Drafting the Blade Clamp

Start with a block that is 25x25x15mm. Move the ruler to the bottom left corner.

Create two 4mm cylinder holes for the screws to pass through. They should be positioned 10.5mm high. One should be 3.5mm from the left edge and the other should be 17.5mm from the left edge. Bonus marks if you can figure out how to place the second hole by measuring 3.5mm from the right edge :).

To give a more finished look, create counterbore holes for the screw heads. Mine are 6mm in diameter, so they are both 9.5mm high and are 2.5mm and 16.5mm from the left edge.

Printing the Tool

Export your file as an STL or OBJ and use it to print your file. I used 30% infill on my FDM printer. Using supports is optional, depending on how well your printer bridges the top of round holes.

If you want to skip the drafting, use the attached file to print the clamp or send it to an online printing service.

Assembling the Tool

We'll start by assembling the lock screw. Use a pair of pliers to squeeze the nut (I'm using a 10-24 knut) into the bottom of the printed knob. Then thread the screw (I'm using a 10-24 x 1 1/2" screw) through the top of the knob and tighten it as far as it goes. It should be nearly flush with the top of the knob.

Drill out the hole in the fence so that the lock screw threads tightly into it. Unscrew the lock screw and put the adjustment bar into the opening in the fence. Feed your lock screw through the slot in the bar and back into the hole. Tighten it until it is snug.

Now, take two M3x25mm screws. Feed them through the blade clamp and into the holes in the end of the adjustment bar. Tighten them most of the way, then put the blade of your choice, either a scalpel blade or a 9mm blade into the clamp. It should be at a fairly low (flat) angle to cut smoothly. Make sure that the tang of the blade doesn't stick out of the clamp or you will have a rough cut!

Now Cut Some Strips...

Set the width of the strip you want to cut. Run the blade along the top of the foam, then flip the foam and cut it again. You'll get nice, clean, repeatable strips.

Using 9mm or even 18mm blades should allow you to cut up to 3/4" in a single pass, meaning it's quite reasonable to cut even 1" foam into strips.

Always use a cutting mat and keep well clear of the blade.